CONTINUOUS COMMISSIONING

e-Bench® supports continuous commissioning by providing a continuous watching brief on the performance of a building and early identification at what point the performance of controls or equipment degrades to the point that it becomes cost effective to intervene. The continuous commissioning process often has a payback period of less than one year.

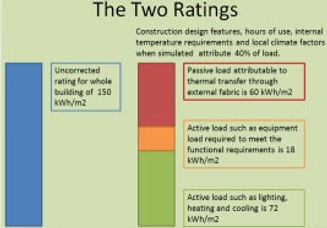

This entails setting up buildings and facilities within e-Bench® using the full benchmarking functionality and then using some initial analysis to determine the baseline load less any consumption associated with heating or cooling. Baseline is lighting and equipment load. Once we have the baseline established we can then determine the actual correlation between the external fabric’s thermal performance and external temperatures.

Using the external fabric’s thermal R values we can also determine the calculated or theoretical design performance of the building. This correlation between external temperatures and heating/cooling loads then becomes our ‘design target’.

By comparing the actual against the design it is then possible to determine the size of the opportunity to be gained by recommissioning controls and systems. By tracking consumption going forward we can ascertain when the HVAC control systems might be in need of recommissioning. Lawrence Berkeley Laboratories in California has identified continuous commissioning as offering some of the best investment returns in energy management.